TOP SECRET: HOW ELASTIC HELPS THE MANUFACTURING INDUSTRY

Preliminary Disclaimer: The title “top secret” can be interpreted in various ways. To clarify, we will not be sharing any confidential information from clients or prospects. Instead, we will highlight a number of exceptional and highly valuable use cases that can also be achieved with Elastic. Since most people are not aware that all this can be done with Elastic, we use the title “top secret.”

THE PROBLEM STATEMENT

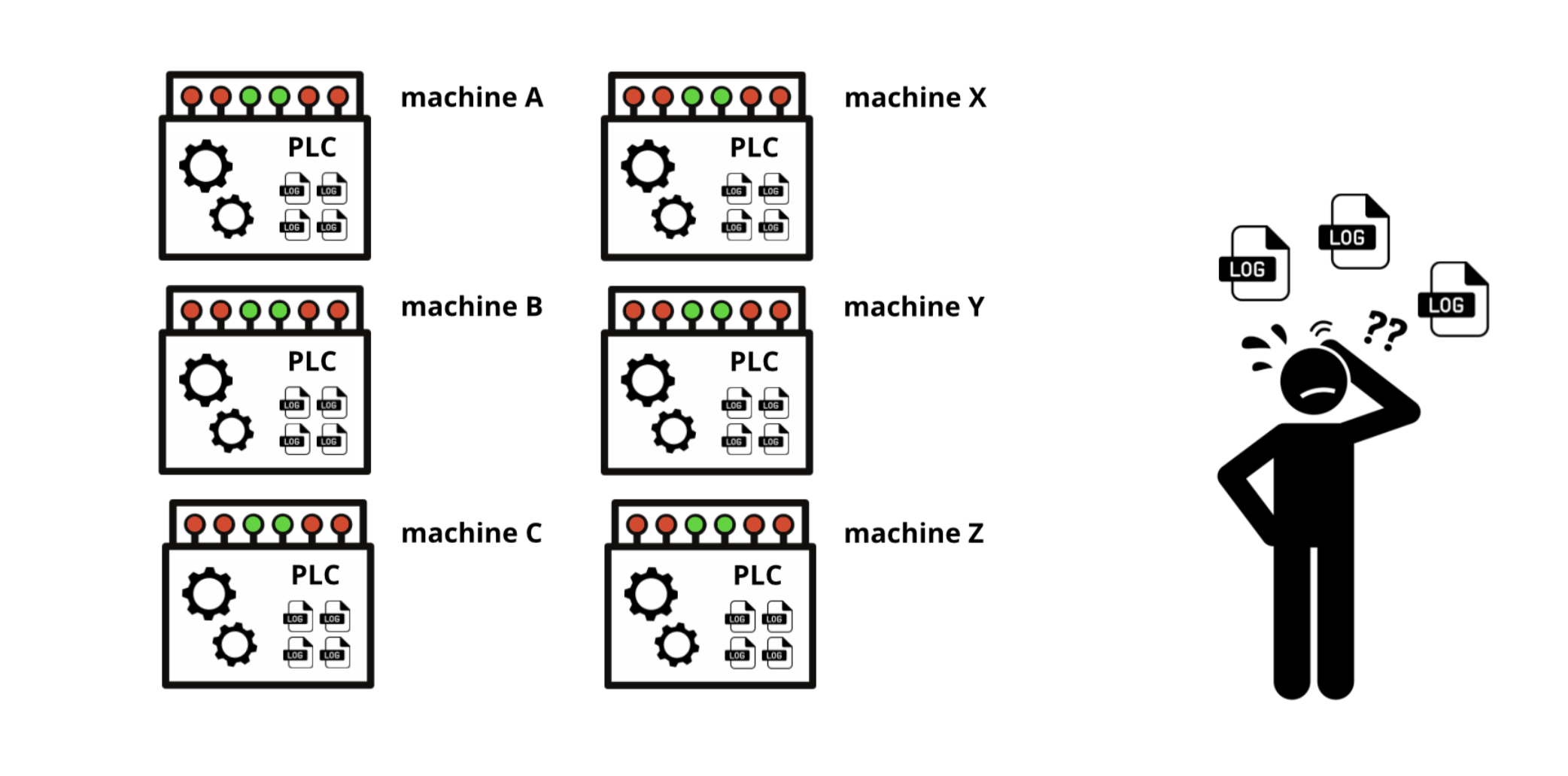

A PLC (Programmable Logic Controller) is an electronic device specially designed for controlling production machines and industrial processes. It forms a crucial part of the production environment. Managing the enormous amount of logs and data from multiple PLCs spread across a large factory can be a significant challenge.

Obtaining a centralized overview of all operational logs and data can be difficult. This can lead to inefficiencies in data analysis, traceability issues, and challenges in performing extensive diagnostics or troubleshooting.

However, quickly and effectively analyzing factory data is important for achieving the following objectives:

- (Preventive) maintenance of machines

- Real-time monitoring of machine conditions

- Quality control and management

- Productivity and efficiency (OEE and production monitoring)

- Safety management

- Energy management

- Supply Chain Management

- Raw material management

THE SOLUTION

These objectives can be achieved by centralizing the data in the Elastic (ELK) stack (Elasticsearch, Logstash, Kibana).

With the help of Elastic Observability, data from various machines and systems can be collected, analyzed, and visualized, all within the Elastic (ELK) stack.

Automating data collection and analysis leads to significant efficiency improvements, as machines are continuously and accurately monitored with minimal human intervention.

BENEFITS OF THE SOLUTION

- Once stored in Elastic, the powerful real-time monitoring and analysis functionality can be used to monitor and optimize the performance and health of the production environment. The need for manual inspections by staff is greatly reduced, significantly lowering costs.

- Additionally, this positively impacts decision-making. Real-time insights and extensive data analysis enable managers to make quickly informed decisions, proactively solve problems, and implement strategic improvements based on concrete, data-driven insights. This not only reduces operational costs but also increases the overall productivity and quality of production processes.

- Reports can also be created to capture and report specific data to your own customers.

- Machine Learning (ML) models can help with the automatic recognition of anomalous data patterns.

- Automatic alerts can be sent to the right people so that problems are resolved very quickly.